In food manufacturing, every variable matters, from ingredient quality to temperature and humidity. But one often overlooked factor silently shapes every stage of production: air quality.

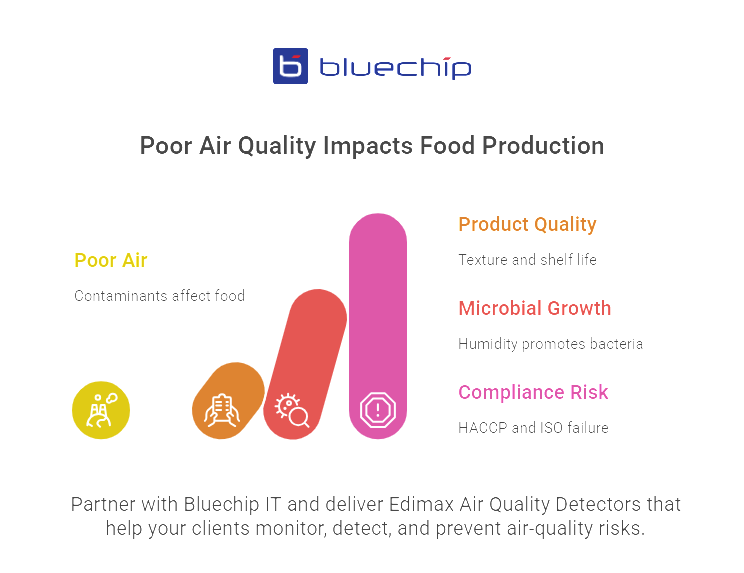

Dust, CO₂ build-up, and microscopic particles can contaminate raw ingredients, affect taste or texture, and even trigger compliance issues. A single lapse in air quality can stop production, lead to costly recalls, and harm your client’s brand reputation.

Across Australia, where climate and environmental conditions vary widely, maintaining clean indoor air has become both a compliance and operational priority. As discussions around air quality in Australia continue to grow, manufacturers are paying closer attention to environmental factors affecting production. That’s why more manufacturers, and their technology partners, are turning to smart air-quality monitoring solutions to stay ahead.

At Bluechip IT, we support resellers and MSPs with innovative solutions from trusted vendors like Edimax, helping your clients protect what matters most: product quality, safety, and uptime.

This blog explores what food air quality really means, why it matters, and how your business can turn this growing demand into opportunity.

Understanding Food Air Quality and Its Business Impact

Food air quality refers to the purity and balance of the air within food processing, packaging, and storage areas. It’s not just about removing odours, it’s about controlling fine particles, VOCs (volatile organic compounds), temperature, and humidity.

The Air Quality Index (AQI), though often used outdoors, is just as relevant for indoors. It provides a framework for understanding how particulate matter (like PM2.5 and PM10) and gases (like CO₂) impact health and equipment.

In a food plant, poor air quality can cause:

- Microbial growth due to excess humidity.

- Contamination from airborne dust or packaging particles.

- Product spoilage from temperature fluctuations.

- Inconsistent production results.

Air quality isn’t only about compliance with Food Standards Australia New Zealand (FSANZ) or local regulations, it’s a business differentiator. Manufacturers who manage it well avoid costly downtime, meet sustainability goals, and maintain customer trust.

Backed by Evidence: Air Quality and Food Safety

Research by CSIRO shows that indoor environments can accumulate pollutants, such as particulate matter and volatile organic compounds (VOCs), which can affect air quality and safety if not properly managed. Their Indoor Air Quality Study notes that even low concentrations of these substances can influence health and sensitive operations, underscoring the need for effective ventilation and monitoring systems in enclosed facilities.

In the food sector, maintaining clean air is also a recognised compliance factor. The Institute of Food Science and Technology (IFST) and industry guidelines on Hygienic Air Quality for the Food Industry emphasise that controlled air filtration and routine monitoring are essential in preventing contamination and ensuring adherence to HACCP and ISO 22000 standards.

In short, clean air is not optional; it’s integral to food safety, regulatory compliance, and product quality.

Partner with Bluechip IT to access Edimax’s smart air-quality solutions designed for food manufacturing.

Explore Edimax Solutions Today >>

The Challenge: Managing Air Quality in Complex Food Environments

Food facilities are dynamic. Production lines generate dust, CO₂ accumulates in enclosed areas, and cooling systems can draw in outdoor pollutants like smoke or pollen.

Common issues include:

- Airborne particles from ingredients and packaging.

- High humidity affects product texture or microbial control.

- CO₂ build-up reduces air freshness and employee comfort.

- Inconsistent ventilation, leading to contamination hotspots.

Manual air-quality checks are limited. They provide only snapshots, not real-time insights. Without continuous monitoring, issues often go unnoticed until product quality suffers or compliance audits flag problems.

The Solution: Smart Air Quality Detection and Monitoring

That’s where Edimax Air Quality Detectors, distributed through Bluechip IT, make a real difference.

These network-ready devices enable food manufacturers and their MSP partners to monitor, detect, and prevent issues before they escalate.

Key features include:

- Real-time monitoring & alerts – Constant tracking of PM2.5, CO₂, temperature, and humidity.

- Centralised dashboards – Access and analyse data remotely for multiple facilities.

- Easy integration – Seamlessly connects to network systems and cloud platforms.

- Low maintenance, high reliability – Designed for long-term performance in industrial settings.

For resellers and MSPs, the value is clear: these detectors create opportunities for recurring revenue through service contracts, reporting tools, and compliance support.

By helping clients prevent air contamination, you’re not just providing hardware; you’re enabling operational resilience and brand protection.

Air Quality in Australia: Why It’s Time to Act

Australia’s climate presents unique challenges for maintaining indoor air quality. From bushfire smoke and dust storms to industrial emissions, outdoor conditions can affect even sealed environments.

Awareness around air quality in Australia is rising, not just among households looking to check air quality in house, but also within industrial sectors where precision and compliance are essential. As businesses monitor air quality today, many are recognising its impact on efficiency, safety, and compliance.

For food manufacturers, investing in smart monitoring is no longer about comfort; it’s about protecting uptime, compliance, and reputation.

And for resellers, this represents a prime opportunity to deliver tangible value to clients, backed by reliable vendor technology and Bluechip IT distribution support.

Monitor, Detect, Prevent, The Channel Way Forward

Clean air is the backbone of consistent, compliant food production. By investing in air-quality monitoring, your clients can prevent contamination, meet regulatory standards, and maintain consumer trust.

As a trusted Australian distributor, Bluechip IT connects resellers and MSPs with world-class solutions like Edimax Air Quality Detectors, helping you deliver smarter, scalable, and profitable solutions for the food manufacturing industry.

Smarter Air, Safer Food

Explore Edimax’s Air Quality Detectors for Food Manufacturing and help your clients monitor, detect, and prevent air quality issues with confidence.