Data centres are built for uptime. Yet sometimes, what brings them down isn’t a power surge or network issue, it’s the air. Dust, smoke, and humidity might seem harmless, but they can quietly damage expensive servers. Fans clog, circuit boards corrode, and systems overheat. When this happens, downtime becomes inevitable and costly.

Across data centres in Australia, from large data centres in Sydney to smaller edge facilities, uptime is everything. However, many operators still overlook one critical factor: air quality in Australia.

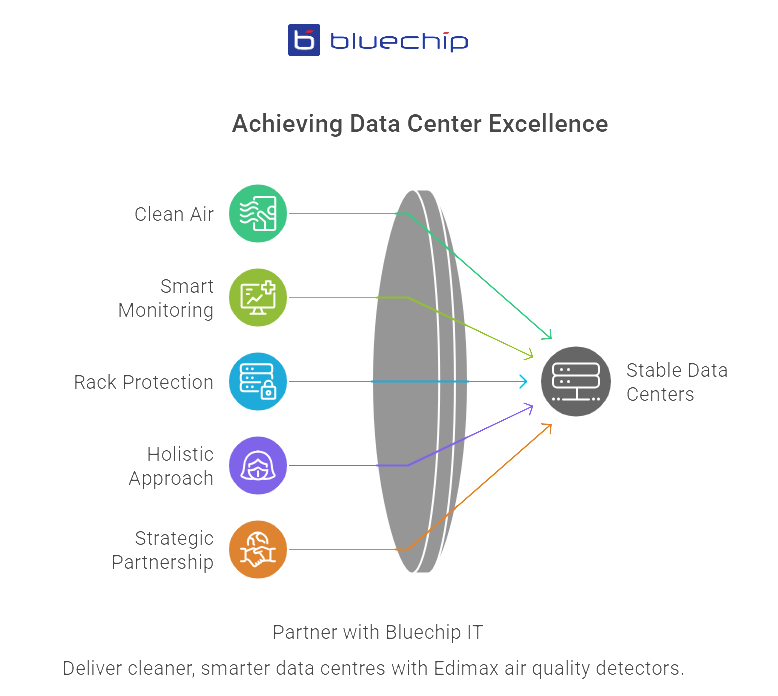

At Bluechip IT, we help resellers and partners protect their clients’ infrastructure with reliable, vendor-backed solutions. One of our trusted brands, Edimax, provides advanced air quality monitoring systems built specifically for data centres in Australia.

In this blog, we’ll explain why air quality monitoring is vital for stable server performance. You’ll learn how poor air affects reliability, what studies reveal about its impact, and how resellers can turn this opportunity into revenue.

The Data Centre Environment: Precision Meets Vulnerability

So, what is a data centre? It’s a precision-controlled environment where every degree, trace of humidity, and particle in the air matters.

According to a 2024 report by the Australian Energy Market Operator (AEMO) and Oxford Economics Australia, data centres in Australia currently account for around 2% of the total electricity consumed across the National Electricity Market — a figure expected to rise to 6% by 2030 as digital demand continues to grow.

This level of energy use shows just how tightly data centres must manage temperature and airflow. Yet even with such control, one factor often slips under the radar: air quality.

Dust, volatile organic compounds (VOCs), and microscopic particles can infiltrate through vents and cooling systems. These invisible intruders may seem minor, but over time they can:

- Block cooling fans and air filters

- Corrode metal connectors and solder joints

- Disrupt the humidity balance and static control

- Reduce energy efficiency

While the Air Quality Index (AQI) is often used for outdoor pollution, it’s becoming increasingly relevant indoors too. Once pollutants enter a sealed data hall, they circulate continuously, silently degrading sensitive IT equipment.

Evidence and Insight: Why Air Quality Matters for IT Equipment

The impact of air quality today on IT equipment isn’t theoretical; it’s real.

When airborne contaminants enter a data centre, they don’t just disappear. Dust and microscopic particles can cling to circuit boards, restrict airflow, and disrupt cooling. Over time, this buildup increases thermal stress and accelerates component wear.

Poor air quality in Australia’s indoor environments also leads to corrosion, especially when humidity levels fluctuate. Even small changes can affect connectors, solder joints, and power supplies, all vital for server stability.

In short, polluted air shortens equipment lifespan and raises maintenance costs. Left unchecked, it can trigger unexpected outages and degrade server performance.

Without continuous air quality monitoring, most operators only discover the problem once downtime occurs, when it’s already too late.

Partner with Bluechip IT to help your clients maintain clean, stable environments. We offer Edimax Air Quality Detectors designed for real-time data centre monitoring.

Explore Edimax Air Quality Detectors ➜

Common Air Quality Challenges in Data Centres

Contaminants enter data centres in Australia in more ways than you’d expect. Even sealed environments aren’t immune.

Here are the most common culprits:

- Outdoor air intake: Cooling systems that draw outside air can introduce dust, smoke, and pollen, especially during Australia’s bushfire season.

- Cleaning chemicals: VOCs from cleaning products, paints, or adhesives release invisible gases that react with metal surfaces.

- Humidity imbalance: Too much humidity causes corrosion; too little leads to static discharge.

- Corrosive gases: In coastal or industrial areas, sulphur compounds attack copper and silver components.

- Old monitoring systems: Manual checks or outdated sensors can’t detect early contamination or sudden environmental changes.

Each of these threats adds up. They slowly wear down equipment, increase energy use, and reduce overall reliability.

That’s why proactive monitoring isn’t a luxury; it’s a necessity.

Smart Monitoring: The Edimax Advantage

This is where Edimax Air Quality Detectors make the difference. Designed for critical environments like data centres in Sydney and beyond, they provide continuous visibility into air conditions, helping operators act before problems occur.

Key benefits include:

- Real-time monitoring of PM2.5, PM10, CO₂, temperature, and humidity

- Network-ready integration for centralised management systems

- Early alerts when readings exceed safe limits

- Data analysis and trend reporting for predictive maintenance

- Compact and scalable design, ideal for any rack or room size

These detectors don’t just detect issues; they help prevent them.

With accurate data, teams can adjust HVAC settings, replace filters on time, and avoid damage before it happens. The result? Improved uptime and lower operational costs.

Channel Benefits for MSPs

For resellers and managed service providers (MSPs), Edimax’s solution creates new value opportunities:

- Offer environmental monitoring services alongside existing network or power solutions

- Generate recurring revenue from ongoing sensor maintenance and reporting

- Strengthen client trust through proactive protection and insights

- Expand service portfolios without high setup costs

At Bluechip IT, we provide Edimax hardware, local support, and pre-sales assistance to help partners deliver reliable, scalable solutions for modern data centres in Australia.

Air Quality in Australia: Why It’s Becoming a Priority

Australia’s climate adds another layer of risk.

Events like bushfires, heatwaves, and dust storms can cause sudden spikes in particulate matter, affecting indoor environments as well. During severe fire seasons, facilities in Sydney and other major cities have had to shut down outside-air systems to prevent smoke and ash from entering server rooms.

Fine particles can still penetrate filtration systems and linger in the air, impacting both human health and equipment performance.

As extreme weather becomes more frequent, air quality in Australia is now part of operational resilience. It’s not just about comfort; it’s about protecting uptime and hardware reliability.

For resellers, this shift presents a clear opportunity. Offering air quality monitoring aligns perfectly with the growing demand for sustainable and dependable IT infrastructure.

For Resellers & MSPs: Turning Monitoring into Margin

Air quality monitoring fits naturally into modern MSP offerings. Here’s how you can turn it into a margin:

- Add it to your monitoring suite. Integrate Edimax sensors into your existing infrastructure dashboards.

- Offer data insights. Provide clients with monthly or quarterly air quality reports.

- Promote compliance and sustainability. Many clients now require environmental monitoring as part of ESG initiatives.

- Upsell upgrades. Bundle sensors with UPS systems, PDUs, and other resilience tools.

At Bluechip IT, we help resellers tap into this opportunity with trusted technology, technical know-how, and ongoing vendor support.

Clean Air, Stable Servers

Air quality might be invisible, but its impact on reliability is clear. By monitoring particulate levels, humidity, and gases, data centres can extend hardware life, improve cooling efficiency, and reduce downtime.

With Bluechip IT and Edimax, resellers can provide smarter, safer, and cleaner data centre environments, while creating new value for their clients.

Deliver Cleaner, Smarter Data Centres

Help your clients protect their infrastructure through reliable, real-time air quality monitoring. Partner with Bluechip IT and start offering Edimax Air Quality Detectors today.